Manufacturing is a cornerstone of economic development, encompassing a diverse array of industries and processes. From automotive and aerospace to electronics and pharmaceuticals, manufacturing examples abound, showcasing innovation, efficiency, and quality. This article highlights notable examples of manufacturing excellence across different sectors, shedding light on their strategies, technologies, and contributions to global markets.

Automotive Manufacturing: Toyota Motor Corporation

Toyota Motor Corporation stands as a paragon of manufacturing excellence in the automotive industry. Renowned for its Toyota Production System (TPS), Toyota has revolutionized manufacturing processes worldwide with its emphasis on efficiency, quality, and continuous improvement. Through practices such as Just-In-Time (JIT) production, lean manufacturing, and Kaizen (continuous improvement), Toyota minimizes waste, maximizes productivity, and ensures superior quality in its vehicles.

Furthermore, Toyota’s commitment to innovation is evident in its development of hybrid and electric vehicles, such as the iconic Toyota Prius. By investing in research and development (R&D) and embracing new technologies, Toyota remains at the forefront of automotive manufacturing, driving sustainability and shaping the future of mobility.

Aerospace Manufacturing: Boeing Company

Boeing Company exemplifies manufacturing excellence in the aerospace sector, known for its cutting-edge aircraft designs, advanced manufacturing processes, and global reach. As one of the world’s largest aerospace manufacturers, Boeing produces a wide range of commercial and military aircraft, satellites, and defense systems.

Boeing’s manufacturing facilities incorporate state-of-the-art technologies, such as automated assembly lines, robotics, and additive manufacturing, to streamline production and enhance precision. The company’s commitment to safety, reliability, and innovation is underscored by its development of groundbreaking aircraft models, such as the Boeing 787 Dreamliner and the Boeing 777X, which set new standards for fuel efficiency, passenger comfort, and sustainability.

Electronics Manufacturing: Samsung Electronics Co., Ltd.

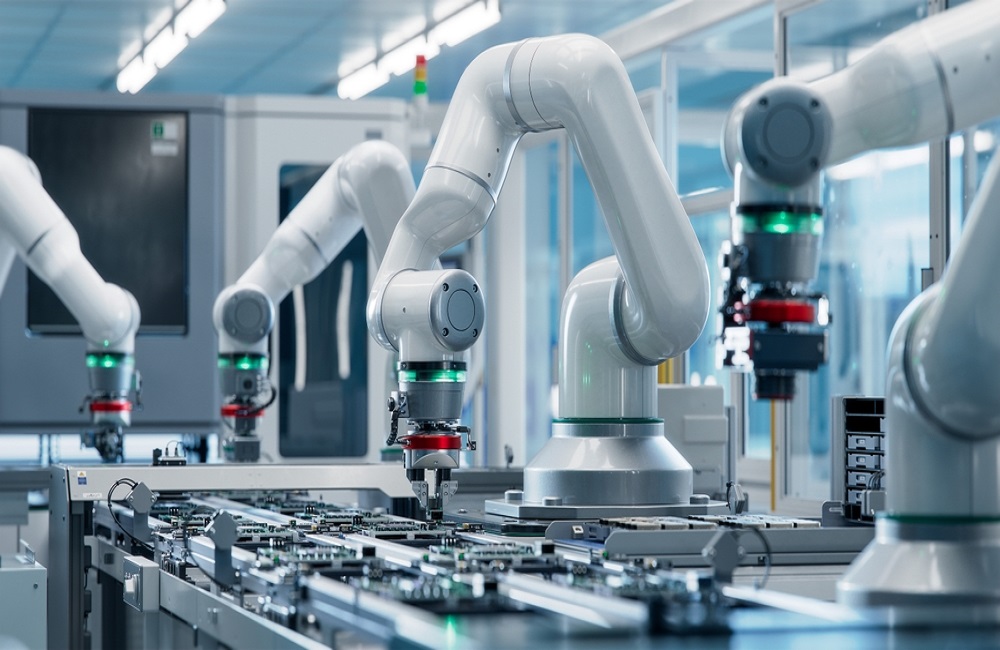

Samsung Electronics Co., Ltd. is a global leader in electronics manufacturing, renowned for its innovative products, advanced technologies, and strong market presence. From smartphones and televisions to semiconductors and displays, Samsung produces a wide range of consumer electronics and components that shape the digital landscape.

Samsung’s manufacturing prowess is evident in its vertically integrated production facilities, which encompass semiconductor fabs, display manufacturing plants, and consumer electronics assembly lines. By leveraging cutting-edge technologies, such as 5G connectivity, artificial intelligence (AI), and quantum dot displays, Samsung continues to push the boundaries of innovation in the electronics industry, driving growth and creating value for consumers worldwide.

Pharmaceutical Manufacturing: Pfizer Inc.

Pfizer Inc. stands out as a leading example of manufacturing excellence in the pharmaceutical industry, known for its commitment to quality, innovation, and global health. As one of the world’s largest pharmaceutical companies, Pfizer produces a diverse portfolio of medicines, vaccines, and healthcare products that address a wide range of medical conditions.

Pfizer’s manufacturing facilities adhere to stringent regulatory standards and quality control measures to ensure the safety, efficacy, and reliability of its products. The company’s innovative approach to drug development, coupled with its investment in biotechnology and research, has resulted in breakthrough treatments and therapies that improve patient outcomes and advance medical science.

Conclusion

These examples of manufacturing excellence underscore the breadth and depth of innovation, efficiency, and quality across different industries. Whether it’s automotive, aerospace, electronics, or pharmaceuticals, manufacturing companies demonstrate a relentless pursuit of excellence in their products, processes, and technologies.

By embracing advanced manufacturing techniques, investing in research and development, and prioritizing quality and innovation, these manufacturers drive progress, shape markets, and improve lives around the world. As manufacturing continues to evolve in the digital age, these examples serve as inspiration for businesses seeking to excel in an increasingly competitive and dynamic global landscape.